ISO Turning Inserts, Tool Holders & Boring Bars - turning insert catalog

It was like the trees were trying to get away from something on the road. Logically, they should have been moving towards the road because it had greater sun light. Why were they moving away from the road ?

I still don’t have an answer to the question, and think it might be one of these: 1. The tar on the road gets uncomfortably hot, and the trees are bending away from the heat. 2. The vehicles moving on the road caused a wind to blow, and the trees were bending away from the road from even as tiny saplings. 3. Even the trees can’t stand the vehicular pollution, and bend away from it. Except the CO2 of course, which they ingest. The other stuff they probably hate – CO, NOx, SO2, the Lead. I like to think it’s the last reason. If I’d been a tree, I definitely would bend away from the pollution.

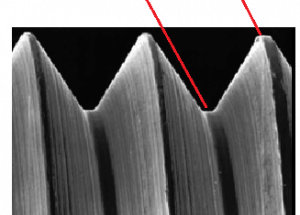

When we select an insert for an operation, we select it based on these characteristics: – How versatile it is in cutting different part contours– Spindle power required to cut– Vibrations during cutting, which are a result of the extent and direction of cutting forces– Strength of the insert and its ability to take heavy cutsThis picture shows how the characteristics change with the turning insert shapes.

Why all those bent trees ? I was jogging near Marina beach in Chennai one morning, and noticed that a lot of trees on the footpath were bent away from the road. Not just a few random trees, but most of them. Either the trunk itself was bent away from the road, or the foliage was concentrated on the side away from the road.

With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers. Register for the world’s largest manufacturing technology forum for free today to stay in the know. Learn more about us.

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

The arrow next to each property indicates the direction in which it increases. Here’s how you interpret the picture:– Vibration during cutting: This is lowest for V shape, highest for R.– Ability to turn complex contours: R is the least versatile, V is the most.– Spindle power requirement: For a given set of cutting parameters, V requires the lowest spindle power, R requires the highest.– Strength of insert: V has the lowest strength, R is the strongest.– Ability to take heavy cuts: V has the least ability to take heavy cuts, while R has the highest.

Action point Please consider these characteristics when selecting an insert for an operation. It takes very little time, but can make a big difference to cycle time and profitability.

18581906093

18581906093