Insert geometries Mitsubishi - cnc insert

Like all tools used on the lathe, boring bar tool height must be checked and adjusted so it is as close to the vertical spindle centerline as possible. Never assume the tool is setup properly just because it was in the lathe cabinet for the machine youre using! If the boring bar is not on vertical centerline it will fail to cut properly, and will be damaged in use.

Its worth repeating: as with all metal cutting processes, stiffness is key when boring, so do everything you can to maximize it: use the largest diameter boring bar and the shortest extension length possible.

Many boring bars do not have alignment flats on them, so it is necessary to orient the top (flat) surface of the cutting edge parallel to the XZ plane of the lathe, as shown in figure 6. The safest orientation is neutral (B) and if you elect to try a different orientation, be careful that adequate cutting tip clearance exists and that the tool tip is set on vertical spindle centerline. Positive rakes are used for cutting weaker materials like aluminum and plastics, and negative rakes are used for cutting stronger materials, like higher strength steels.

The easiest tool to use for bore measurement is also the least accurate: dial calipers. These typically arent very accurate (within a couple thousandths of an inch) on smaller bores (0.5) because the inside jaws have flats ground into them that prevent them from measuring the true size of the hole.

Figure 5: Example of properly selected brazed carbide boring bar (left) and indexable carbide boring bar (right). Notice how short and stiff the selected bars are in relation to the respective workpieces.

Figure 2: Example of brazed carbide boring bars, where a small piece of tungsten carbide is brazed onto a cheaper steel shank. When the carbide chips, the boring bar is either reground (which is difficult to do well) or discarded.

1. Remove as much material as possible by drilling, since its the most efficient method of material removal. When doing this, be sure to leave enough stock for the next step. Leave the bore about 0.050 small in this case.

3. Do not try to sneak up on the final size. As anti-intuitive as it may sound, the best results are not obtained by making smaller and smaller cuts until you reach the desired size because of the safe minimum depth of cut discussed in Step 3 above. The best results are obtained by repeatedly removing a similar amount of material on each pass and using the resulting measurement data to make small adjustments to each subsequent pass. On the 1 303 example piece, the final cut would remove 0.005 to 0.010 from the diameter to bring the part into final size tolerance.

Telescoping gages can measure deeper bores than inside micrometers, which allows you to measure the amount of taper in a bore, not just the diameter close to the surface of the part.

Bore measurements can be made using several tools, depending on the budget, operator skill, and required measurement accuracy.

TIP: A safe maximum depth of cut for a boring bar is twice the corner radius. Its important to understand there is also a safe minimum depth of cut, below which the tool constantly transitions between cutting and smearing, leaving a very inconsistent size and finish. This safe minimum depth of cut is typically around 0.002 to 0.005 depending on the material. Harder / stronger materials usually can tolerance a smaller minimum depth of cut.

2. Perform a few test cuts to check how the boring bar is cutting. Rarely will a boring bar cut perfectly. If you try to remove 0.010 off the diameter of the bore, it may only remove 0.0096 on the first pass and another 0.0004 on the spring pass. (A spring pass is simply a second pass that helps compensate for tool or part deflection during the first pass.) Its important to make a couple passes and write down how much each removes so you can take the average and know what to expect when it matters.

Telescoping gages are commonly used to measure bores, but require a lot of operator skill to provide repeatable and accurate results. After being inserted into the bore, a small amount of torque is applied to a friction lock, the telescoping gage is swept through the center of the bore, and subsequently measured with a micrometer. The challenge is applying the proper amount of torque to the friction lock, as too little results in the gage not holding the true bore reading once removed, and too much results in the gage distorting and showing a reading that is larger than the actual bore size. Like all metrology tools, practicing on a bore of known size (like a bearing race for example) is the only way to become proficient in the use of telescoping gages. Used in sensitive hands, telescoping bore gages are accurate to around +/-0.0005.

TIP: When using boring bars, its best to begin with a cutting speed equal to half the typical computed value and work your way up if vibration and tool life allow it. The primary reasons are the reduced stiffness due to the cantilevered nature of boring bars, as well as the difficulty of providing consistent lubrication to, and chip evaluation from, the cutting edge of the tool unless flood cooling, as in a CNC lathe.

Like parting, boring on the lathe is a simple operation in theory, but requires close attention to detail for success when precision is important (i.e. to within 0.001 of target size). For those who like to take notes as you read, heres a condensed pdf version of this document.

Figure 3: Example of indexable carbide boring bars, where a replaceable tungsten carbide insert is attached to a machined pocket in a steel or carbide boring bar shank. When the carbide insert chips, it can be easily and quickly rotated to another corner (indexed) or replaced with another insert.

Next are small hole gages, which are also inserted into a bore until a small amount of drag is felt and subsequently measured with outside mics. Used in sensitive hands, small gages are accurate to +/-0.0005.

Using a boring bar to simply enlarge an existing hole is a straightforward process. However, when trying to hit a particular size and tight tolerance, everything begins to matter: boring bar selection and setup, cutting edge geometry, tool deflection, lubrication, cutting parameters, chip evacuation, part temperature, and our ability to measure the bore accurately and precisely. If you cannot force yourself to be a little OCD, you might not be good at precision boring J.

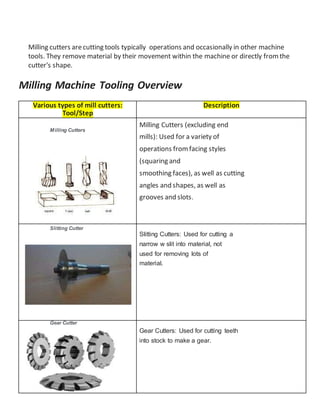

Milling cutters are cutting tools used in milling machines and other machine tools to remove material. There are various types of milling cutters that are used for different operations like shaping faces, cutting slots, making gears, and more. Some common types include end mills, slitting cutters, gear cutters, and face mills. End mills can cut in all directions and are used for operations like profiling and slot cutting.Read less

Figure 1: Examples of HSS boring bars: one piece (left) and indexable (right). When the cutting edge wears or chips, it can be easily re-tipped on a standard grinder and honing stone.

Figure 4: Larger corner radii are stronger and better for roughing, but smaller corner radii typically produce more accurate bore sizes and better surface finishes (at reduced feeds).

Bore gages are essentially precision telescoping gages with dial indicators built in. In use they are first calibrated using an outside micrometer and then the actual bore size is measured relative to that calibration using the dial indicator . Bore gages are accurate to +/-0.0005.

Gage pins are another way to measure precision holes. Gage pins are available in virtually any size and typically manufactured (precision ground) to +/-0.0002 tolerance.

The best tool for accurately measuring bores is a 3 point internal micrometer; however, these are also the most expensive option because each has a limited measurement range, so several units have to be purchased to cover a decent range of sizes. 3 point micrometers are accurate to +/-0.00005 to +/-0.0001.

The second easiest tool to use is an inside micrometer. However, inside mics typically only work well for measuring shallow bores up to approximately 3 in diameter. They are accurate to about +/-0.0005.

As with all metal cutting processes, stiffness is key when boring, so do everything you can to maximize it: use the largest diameter boring bar and the shortest extension length possible.

There are three general types of boring bars: high speed steel, brazed carbide, and indexable carbide. The benefits of HSS are that it is cheaper and tougher. The benefits of carbide are that it can tolerate much more heat (i.e. it can cut 2.5 5 times faster than HSS), and it has a modulus of rigidity that is about 2.5 times greater than steel.

Consistency is crucial to obtaining repeatable results when using boring bars. Meaning, you want to vary the fewest parameters possible during each cut, and preferably only one at a time. Anything that affects the cutting force at the tool tip will change the amount of material removed, or the surface finish obtained: depth of cut, feedrate, lubrication, corner radius, part temperature, etcetera.

18581906093

18581906093