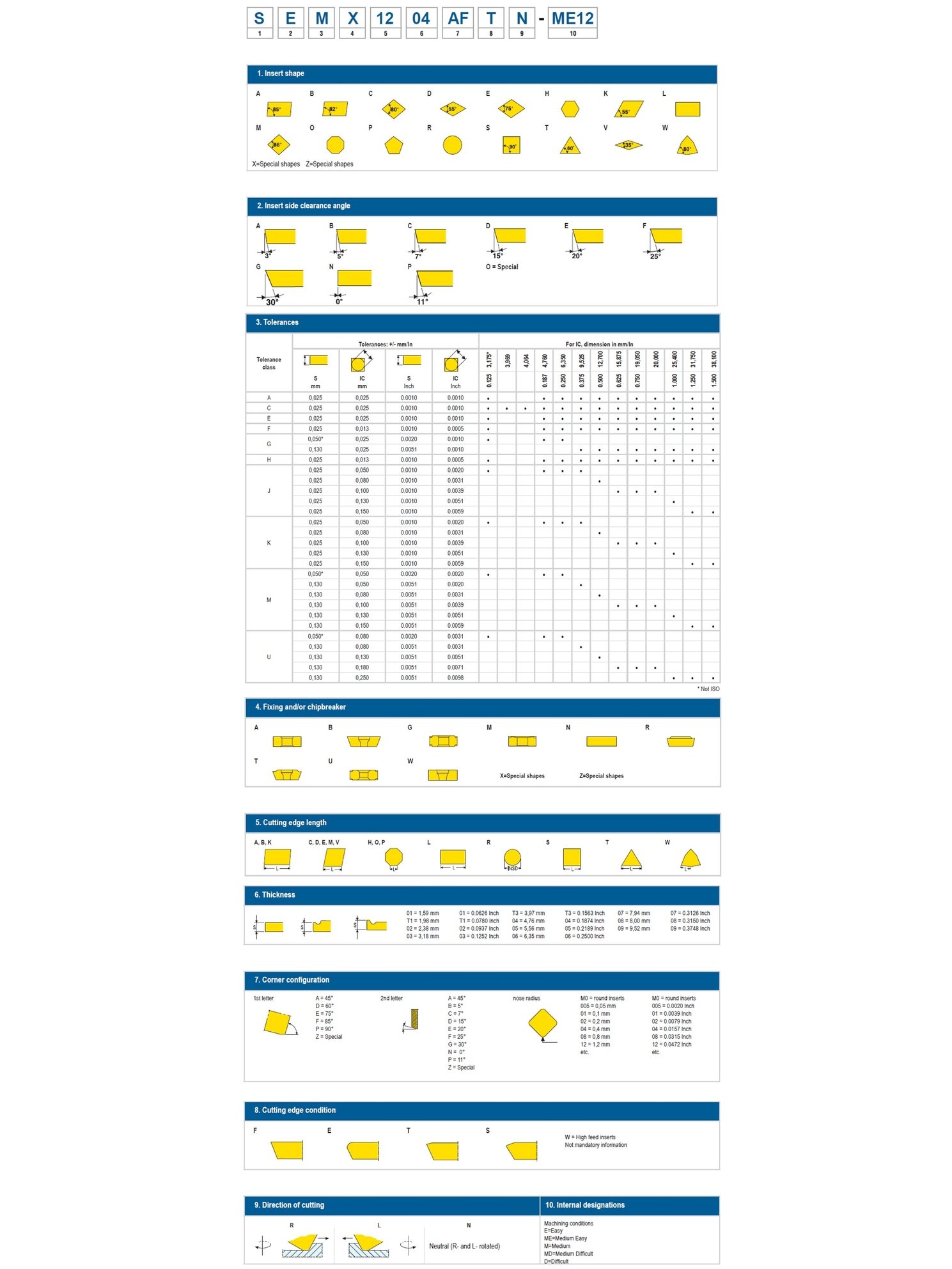

Turning Insert Designation System Code Chart - turning insert identification

Face grooving test results GY series can achieve stable machining at the cutting conditions which created vibration with a conventional modular type tool.

These cookies enable this website to provide enhanced functionality and personalisation. They may be set by us or by third party providers. Functional cookies are used by social networking services to track the use of their built-in features. For example, these cookies allow you to share pages from this website with your social network. Advertising cookies may be set through this website by our advertising partners based on the data obtained. They identify your unique browser and Internet device and may be used to provide anonymized demographic data, build profiles of your interests, and display advertising relevant to those interests.

![]()

The system is designed so that each important feature and dimension of the insert is shown using a code system. This becomes the name of the insert.

Applicable for various diameters of face grooves by the wide array of modular blades with different grooving diameters.

Necessary cookies are used to help this website function properly. For example, they provide login retention functionality.

The TRI-LOCK system ensures the blade is securely fixed in 3 directions (side, front and top), giving high rigidity for stable grooving performance.

![]()

THE ISO designation system for indexable insertsThe ISO designation system for indexable inserts (ISO 1832) is a standardized system to name an indexable insert.The system is designed so that each important feature and dimension of the insert is shown using a code system. This becomes the name of the insert. This system has several advantages:Unique naming of an indexable insert (supplier independent)All important features and dimensions are clearly stated in the nameSome code positions relate to the insert carrier in which the insert can be mounted It's important to remember that the ISO designation system is not a system that standardizes the quality of the insert. Neither the carbide grade nor the cutting geometry is standardized in this designation system. This is an example for milling inserts. For other applications, you can refer to the relevant Machining Navigator. Do you want to know more?Contact Us Inline Content - SurveyCurrent code - 5fce8e61489f3034e74adc64

Analytical cookies collect information about your use of this website in an anonymous and aggregated form. These cookies are used to analyze and improve the functionality of this website.

It's important to remember that the ISO designation system is not a system that standardizes the quality of the insert. Neither the carbide grade nor the cutting geometry is standardized in this designation system.

18581906093

18581906093